홈 / 모든 / Microchannel heat exchanger /

HZSS Fuel-Oil Heat Exchanger Carbon Steel Power Generation Plants

HZSS Fuel-Oil Heat Exchanger Carbon Steel Power Generation Plants

Ensure stable temperatures for fuel and lubricating oil to prevent overheating or excessive cooling, which can affect engine performance and longevity.

| 카테고리 | Microchannel heat exchanger |

|---|---|

| 브랜드 | SHENSHI Heat Exchanger Manufacturer |

| Materials | titanium alloy, stainless steel, high-temperature |

| Applicable media | Antifreeze, flue gas, fuel-oil, etc. |

| Customized | Support |

| 포트 | Shanghai/Ningbo/Guangzhou |

| 결제방식 | L/C, T/T |

| 업데이트 시간 | 2025/6/23 |

상세보기

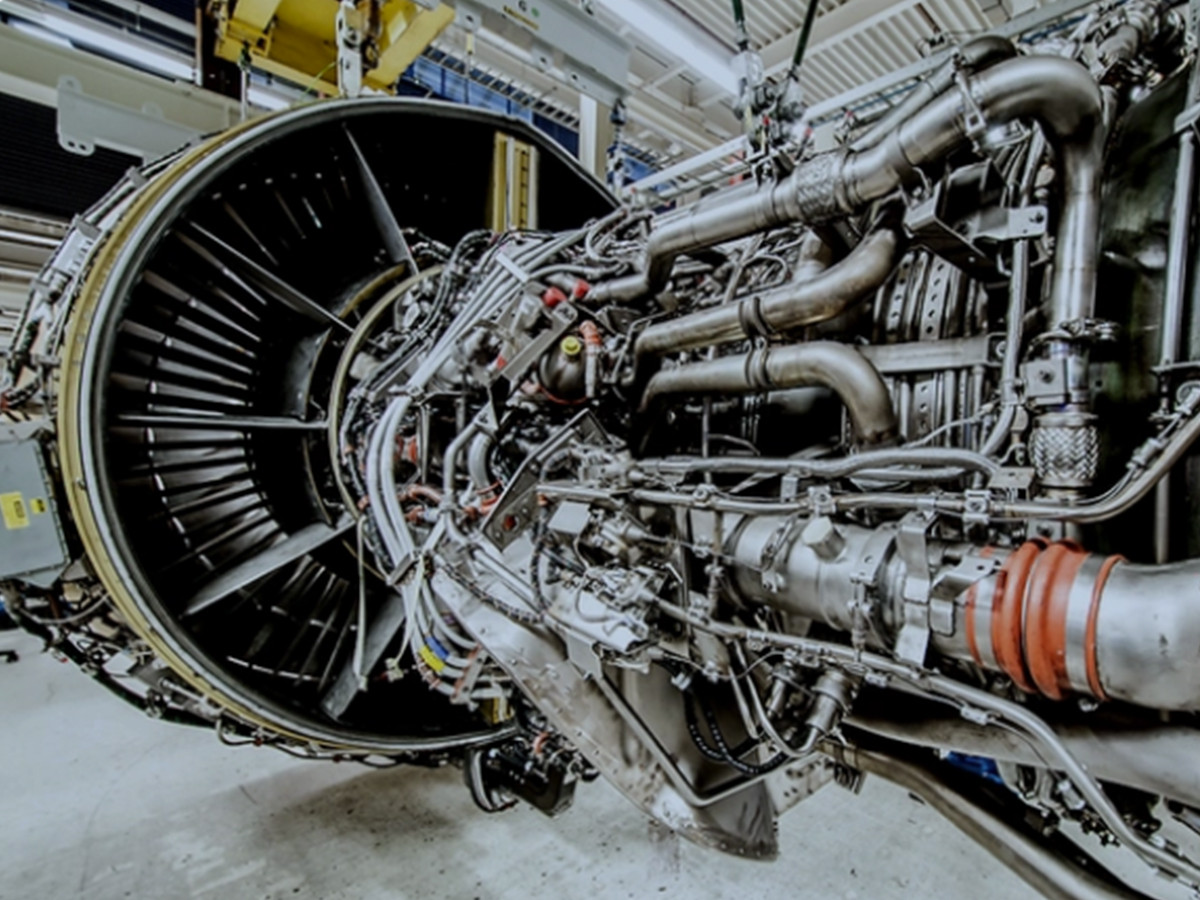

Fuel-Oil Heat Exchanger

Used in the aircraft engine fuel system, it cools and transfers heat for fuel and lubricating oil in high-temperature, high-pressure environments, ensuring a stable supply of fuel and normal engine operation. During operation, the fuel and lubricating oil enter the interior of the heat exchanger through the inlet pipeline, where they undergo heat exchange with external air in the tube bundle. The cooled fuel and lubricating oil then return to the fuel system through the outlet pipeline. The heat exchanger features a lightweight design, corrosion resistance, and high heat dissipation efficiency, effectively improving the fuel efficiency and performance of the aircraft engine, ensuring flight safety.

Features

1.Corrosion Resistance: Titanium alloy offers excellent corrosion resistance, capable of withstanding various harsh environments in the aerospace sector.

2.High Efficiency: Utilizes microchannel structures for efficient heat exchange, reducing energy consumption and improving energy utilization efficiency.

3.Lightweight Design: Titanium alloy has a low density, resulting in a lightweight product that reduces the load on the aircraft.

4.High Reliability: With high strength and toughness, titanium alloy can operate stably under high temperatures and pressures, ensuring the normal functioning of the fuel and lubricating oil system.

5.Long Service Life: Due to the corrosion resistance and stability of titanium alloy, the heat exchanger has a longer lifespan.

Working principle

When the fuel and lubricating oil enter the heat exchanger, they perform heat exchange with the titanium alloy tube walls, which absorb the heat from the oil and transfer it to the external cooling medium. This process cools the fuel and lubricating oil while maintaining them within an appropriate temperature range.

Related industries

Aerospace Engine

Used for cooling the fuel and lubricating oil systems of aerospace engines, it features excellent corrosion resistance and high-temperature performance, capable of withstanding the high temperatures and pressures generated by aerospace engines, ensuring normal engine operation.

구매메세지 보내기

신뢰할 수 있는 저탄소 열 관리 솔루션을 찾고 계신가요? 저희는 고객에게 제품 상담, 기술 지원 및 맞춤형 서비스를 신속하게 제공해 드립니다. 더 자세한 정보는 언제든지 문의해 주세요.

- 이름

- 전화

- *제목

- *내용